Experiment 4 - Particle Shadow Velocimetry

A. Borgoltz, M. Szőke, W. George, and T. Meyers

Last Modified 23 February 2023

1. Introduction

The most common flow velocity measurement device is probably the

Pitot-static probe (used in Experiment 3). This is a rugged and

inexpensive device that in many situations can be used to give

accurate and reliable velocity measurements. However, Pitot-static

probes cannot measure velocity fluctuations associated with

turbulence or unsteadiness. Furthermore, the time average

velocities they can measure are inaccurate in regions where the

flow is highly turbulent, reversing or of unknown direction (as in

the center of the wake of a circular cylinder). Unfortunately such

regions are often of the greatest engineering interest.

More sophisticated techniques can be used to obtain such

information. An increasingly commonly used technique is particle

image velocimetry. Particle Image Velocimetry (PIV) is a

non-intrusive measurement that utilizes a predefined laser plane

to illuminate tiny particles dispersed throughout the fluid in

quick succession. The change in particle position between

successive images can be used to determine the velocity of each

particle in the images and therefore provide estimate of the flow

field over the entire imaging area. This technique has the

advantage of providing measurement over a (possibly) large

area in a short period of time. The disadvantages are the

cost of the equipment (cameras can cost upwards of $10,000 a piece

and lasers routinely cost $40,000 and up), the need for optical

access for both the cameras to image the flow and for the laser.

One of the greatest disadvantages of modern, high-speed PIV

systems is that they rely on Class IV high-power lasers. Such

laser systems pose a health and safety risk to their users and to

their surroundings as they can damage tissues, cause skin burn, or

in extreme cases, lead to the loss of sight.

Dr. Todd Lowe, a professor in the Aerospace and Ocean Engineering

Department, is a leader in optical diagnostic tools in fluids and

has extensive experience with PIV in particular. The video below

shows particles flowing over a flat plate (flow direction is bottom

to top). This video is quite remarkable since you can discern

individual particles all the way to the wall. This is a very

challenging measurement that uses fluorescent particles (different

from the ones you will be using in this experiment). As you get

closer to the wall, the laser reflects off the surface of the flat

pate and creates a glare that saturates the camera sensor. As a

result, no particle can be distinguished in the glare region. By

using particles that will absorb the laser light and emit light at a

different wavelength, you can filter out the laser light entirely

(by using narrowband filters on the cameras that will allow only the

scattered light to be imaged). This technique is being pioneered by

Dr. Lowe with support from NASA with some early results below. Note

how well you can see the particles all the way to the wall (the

white line in the video) and how well those particles highlight the

turbulent motion inside the boundary layer.

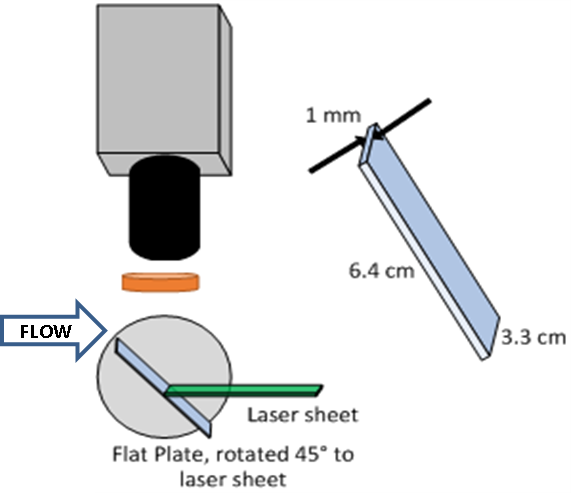

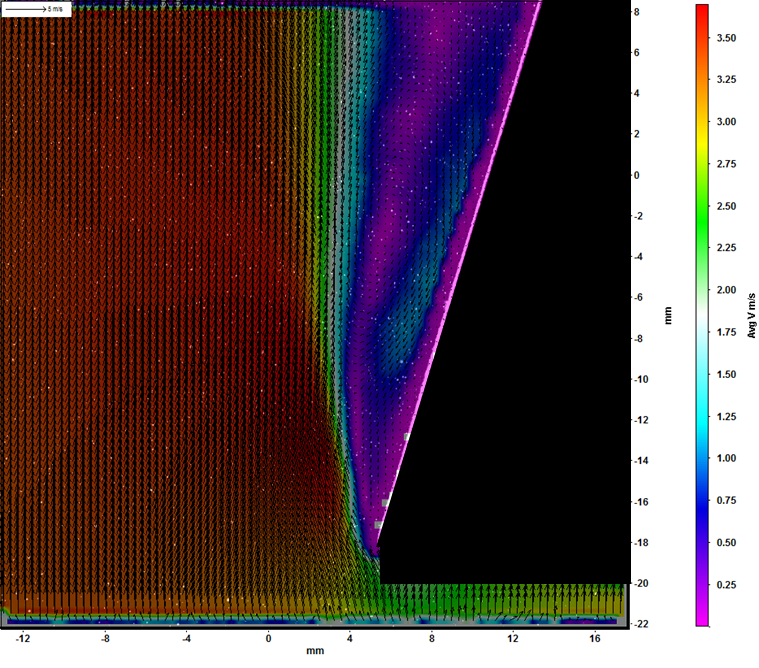

Figure 1. Fluorescent Particle Image Velocimetry Technique

(courtesy of Prof. Todd Lowe from Virginia Tech) (a)

Experimental Setup, (b) Animation of particle motion as acquired

by PIV camera (flow direction is bottom to top), (c) PIV results

for the velocity magnitude (flow direction is bottom to top ;

dark triangular area in the bottom right corner is the region

shielded from the flow by the flat plate where there is

therefore no significant data).

Partially as a response to the health and safety risks associated

with PIV lasers, researchers at Penn State University proposed an

alternative but similar method to PIV: the Particle Shadow

Velocimetry (PSV). PSV relies on the use of a generalized light

source, such as bright LEDs, which is significantly less expensive

than high-speed powerful lasers. In this configuration, the light

travels along the optical axis of the camera and the measurement

volume (i.e. flow field of interest) is located between the light

source and the camera, see Figure 2. As its name suggests, shadows

of the flow seeding particles are captured in the images obtained

by the camera - you might imagine the result similar to watching a

sunset over the horizon when objects, such as trees, will turn

into silhouettes. Using the proper image processing algorithms,

the images from the camera can be inverted such that they will be

identical to images obtained by PIV systems. Therefore, PSV can

offer the same capabilities as PIV at a significantly reduced cost

while it can also eliminate the high risks associated with using

Class IV lasers. In this experiment, you will be using a

high-speed PSV system to measure the flow field in a

closed-circuit water tunnel in the wake of a cylinder.

Basic principles

While you may be familiar with the operating principles of PIV,

the operating principles of PSV will be introduced in the

following paragraphs. Your experiment will use the same principles

to obtain flow velocity data. The working principle of particle

shadow velocimetry is to capture the shadows of particles in the

flow to allow us to track their position between successively

acquired images. To do so, the flow is imaged by one or two

high speed cameras in order to accurately measure the flow

velocity components. There are generally two types of PSV (or also

PIV) setups: 2-component and 3-component (also known as stereo PSV

or PIV). 2-component PSV uses only one camera and yields 2 of the

velocity components within a plane, whereas stereo PSV uses two

cameras and gives you the full 3 components of velocity over a

thin volume of fluid. Stereo imaging works in much the same way as

how our eyes allow us to accurately perceive distance. Stereo PSV

is more complex to implement and process however, due the addition

of the second camera, so for this lab we will focus solely on a

2-component PSV procedure.

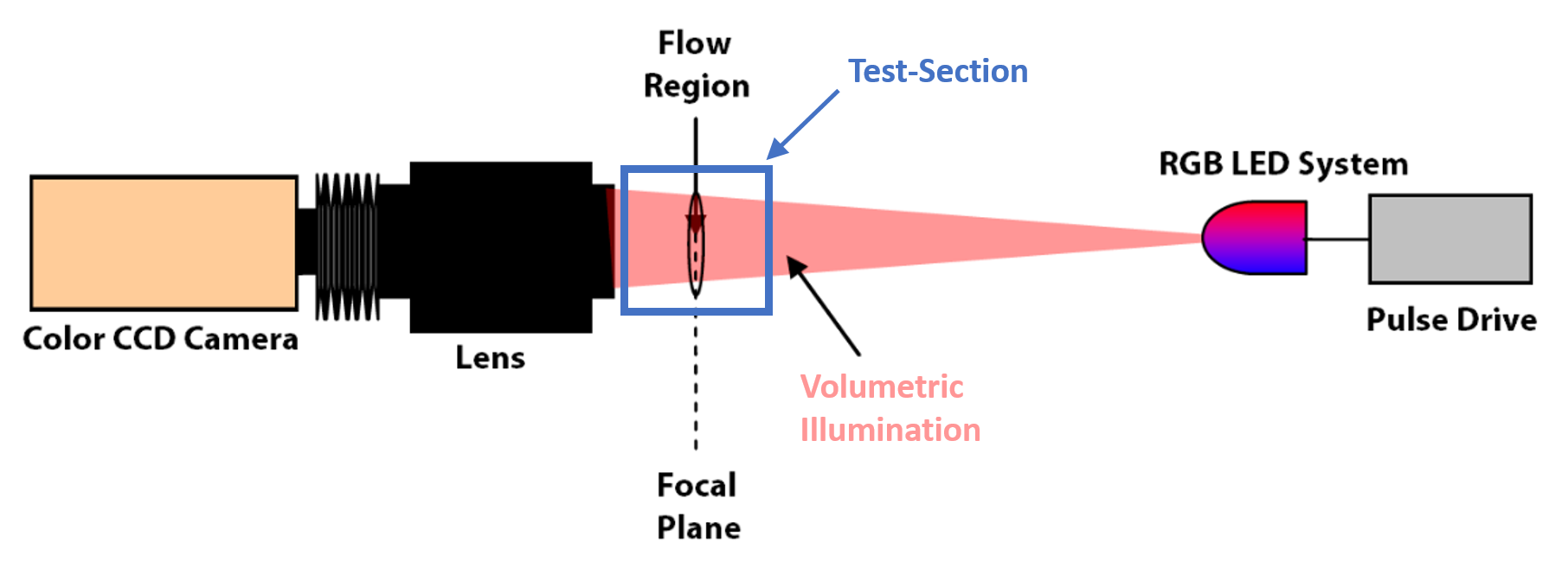

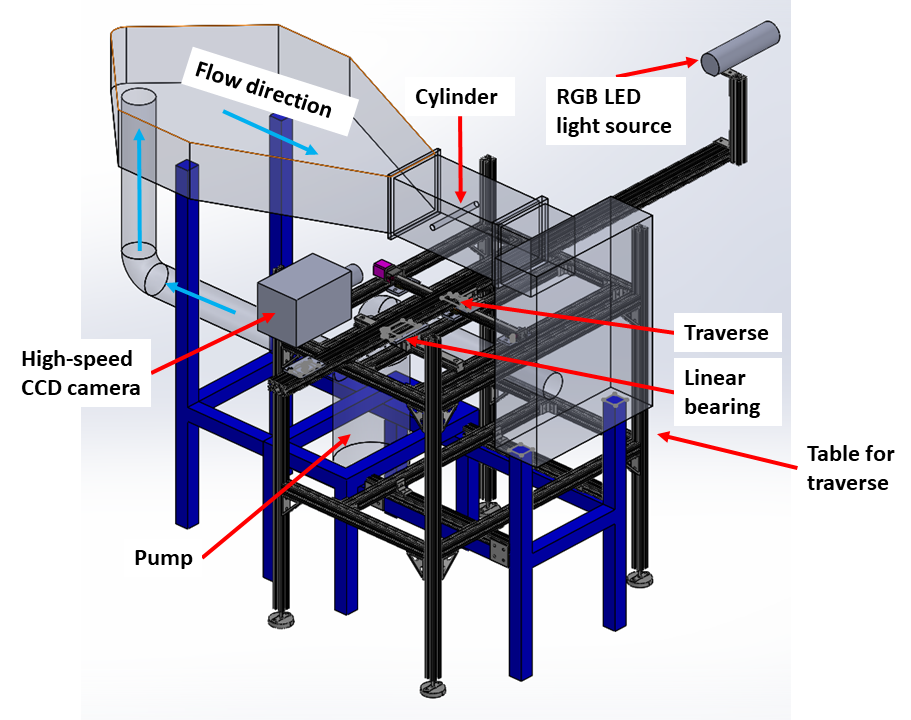

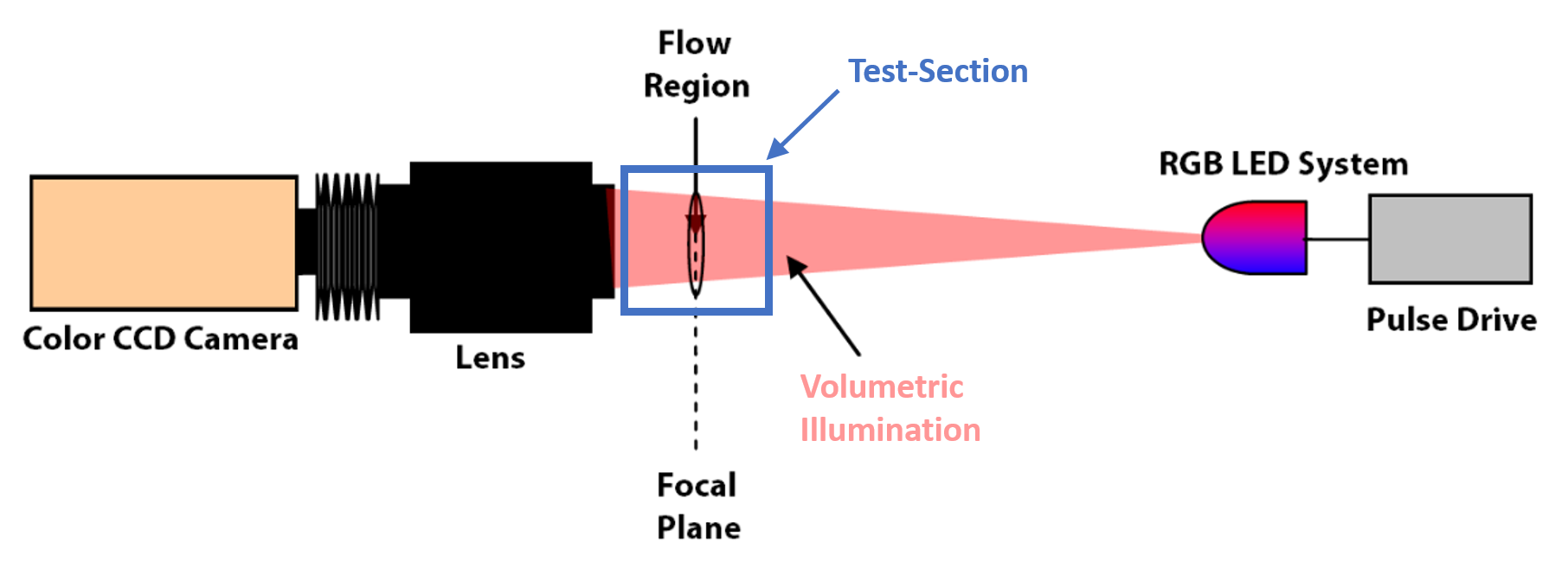

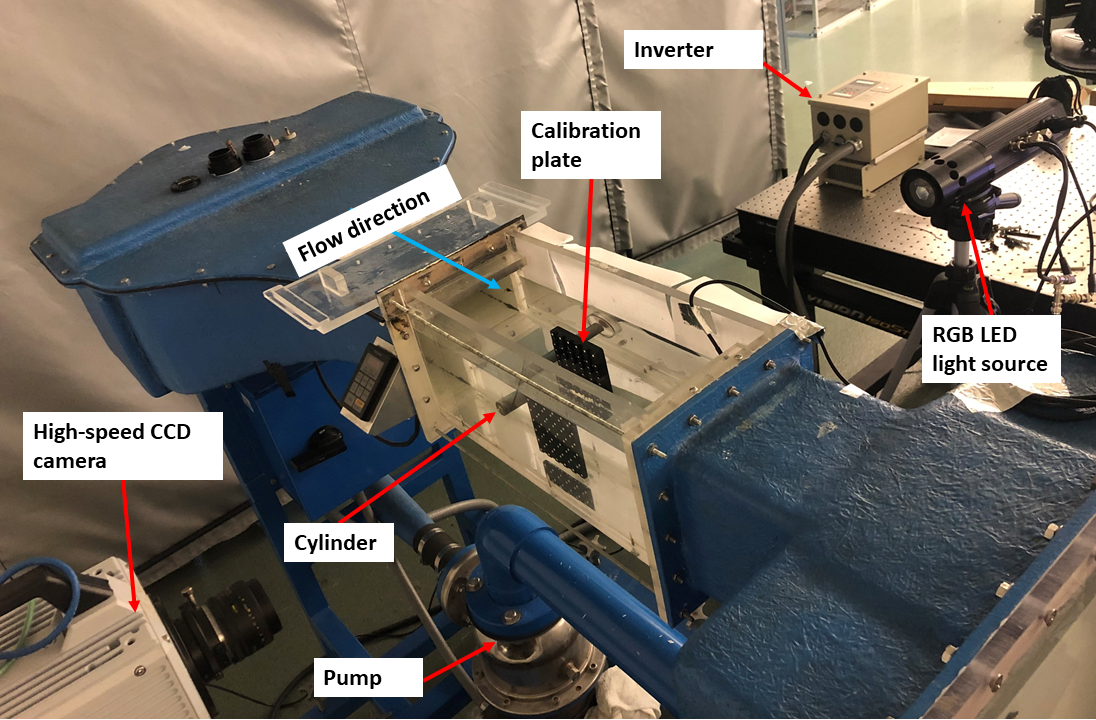

A typical 2-D PSV setup can be seen in Figure 2 below. The light

source is located on the right, where an RGB (red, green, blue)

LED (light emitting diode) light source is used. The light passes

through the flow where flow seeding particles are present. The

particles block the path of the light from the LED as it

propagates to the lens and then to the CCD (charge-coupled device)

sensor of the high-speed camera. In the case of a PSV setup, the

focal plane and focal depth of the lens will determine the region

of the fluid where measurement data is obtained. Only in this thin

volume of fluid will the shadows of the particles will be observed

(i.e. sharp in the image) by the camera. One component of the

optical setup is missing from Figure 2, which is a light diffusing

sheet between the focal plane and the LED light. In the current

experiment, a light diffusing sheet is responsible to evenly

distribute the light arriving from the LED light to the camera.

Figure 2. Typical 2-D PSV setup. Picture adapted from INNSI,

found at https://innssi.com/particle-shadow-velocimetry/

Particles

As mentioned above, tiny particles must be present in the flow for

a measurement to be made. These are referred to as seed particles,

or just seeding. It is important that these particles be small

enough to accurately follow all the movements of the flow. That

way, when we measure the velocity of the particles, we are also

measuring the velocity of the flow. These particles are either

dissolved or aerosolized in the flow. Note that, even in well

seeded flows, the particles form only a minuscule fraction of the

volume of the fluid. They therefore have no significant effect

upon the flow. In this experiment, you will be using Cospheric

gray microspheres with a 250-300 micrometer in diameter as seed

particles whose density is identical to that of water, therefore,

they are buoyant in the water tunnel used in this experiment.

Figure 3. The green seed particles moving in the water tunnel

Light Source

In this PSV experiment, you will be using a time-pulsed RGB LED

light source (seen in Figure 4b), custom designed and built by

INNSI for PSV applications. The light pulses are timed such that

they occur during the time window when the camera is recording the

images. This increases the signal-to-noise ratio of particle

shadows seen in the pictures.

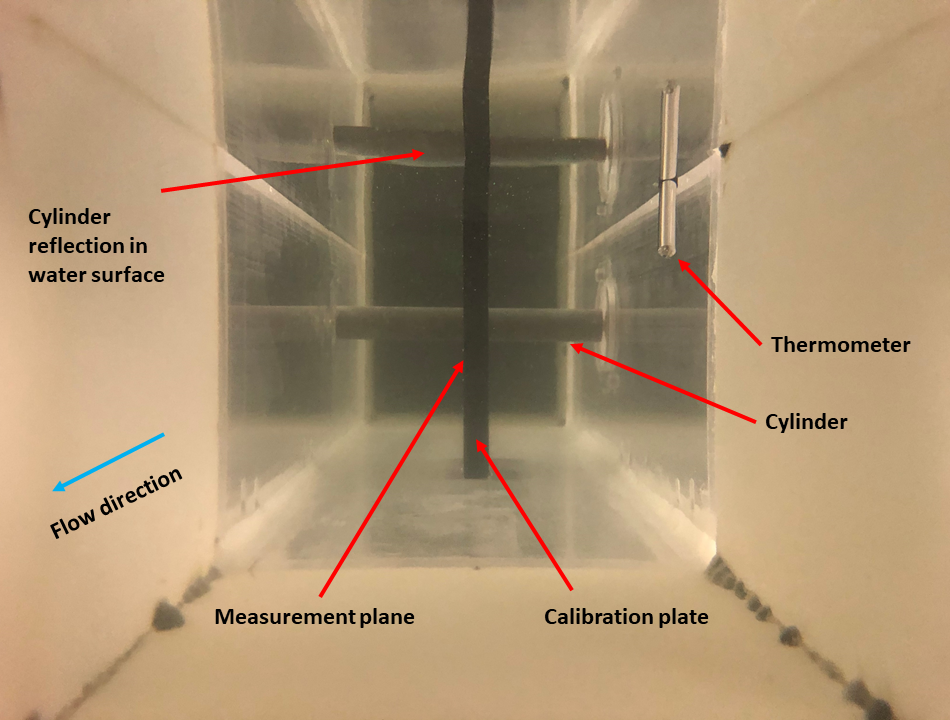

Imaging System

The focal plane of the optical system (camera+lens) will be

located so that it lays in a streamwise plane perpendicular to the

cylinder span, along the centerline of the test-section. The

high-speed camera will be placed perpendicular to the test section

volume as shown in Figure 4b.

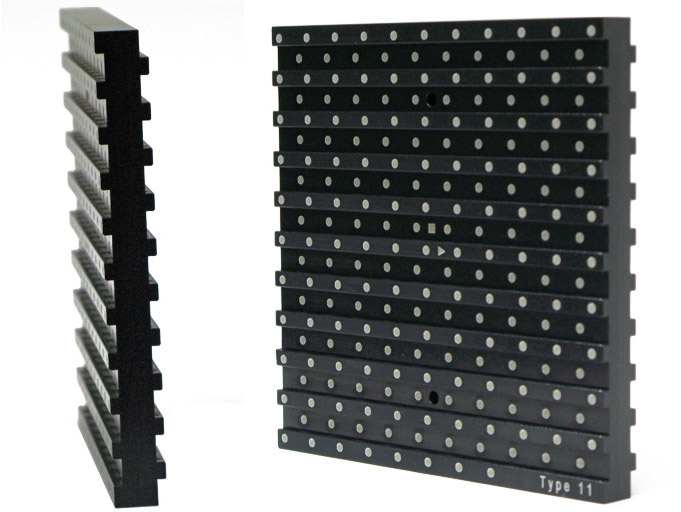

A calibration plate with rows and columns of shaded circles (3.2

mm in diameter and spaced 15 mm apart) is used to precisely focus

the camera and to determine the measurement location. An example

of such plate can be seen in Figure 4a and 4b. The calibration

plate is placed into the test section and the camera lens is

focused to the front surface of the calibration plate. A built-in

software can then accurately determine the relative position of

the camera with respect to the focal plane by acquiring images of

the calibration plate and triangulating the position of each white

circle. An optical calibration is then obtained which is

the relation between spatial units and pixels, i.e. a calibration

constant of pixels/mm is found. From this, the observed particle

displacement measured in pixels is related to particle, or flow,

speed by the software you will be using.

Figure 4. PSV Camera calibration.

(a) Calibration plate from manufacturer LaVision. The dots are precisely located.

Note that some columns of dots are out of plane to allow for

stereo-PSV camera calibration

(to allow for out of plane calibration).

(b) The calibration plate used in the water tunnel.

(c) Side view (looking upstream) of the test volume.

Signals and signal processing

Once the high speed camera is precisely focused, it is

synchronized with the pulses of the LED light so that when you

look at two successive images, the particles will have moved a

couple of pixels. This particle shift between each set of

successive set of images is important for post processing because

the processing code breaks down the images into smaller pieces

called interrogation windows. Within these interrogation windows,

the processing code will compute the cross-correlation between the

interrogation windows of two consecutive images and calculate the

most likely displacement for the entire group of particles inside

the interrogation window. Knowing the time delay between the two

consecutive images, the velocity can be determined. It is

important to note that you want as many seed particles as possible

while still being able to distinguish between the particles for

optimum results.

Once the cross-correlation between a pair of interrogation

windows has been completely calculated, the window shifts over or

down while usually still maintaining a 50% overlap with the

previous interrogation window. This overlap increases processing

time, but it allows for a greatly reduced uncertainty in stitching

all of the interrogation windows back into the full image with

calculated velocity vectors. The processing results in the entire

velocity field in the plane of the laser sheet. With a single

camera, the velocity field measured is two-dimensional (like in

your experiment). For 3D velocity measurements, a second camera is

required and the technique becomes stereo-PSV. From this velocity

field, one can extract information about the flow structures, wake

profiles, and vorticity field. You are encouraged to search for

applications of PIV and PSV measurements in the aerospace and

ocean engineering community before your experiment so that you can

get a wider picture of this method's use and applicability.

2. Apparatus and

Instrumentation

An overview of this experimental setup is provided in the video below:

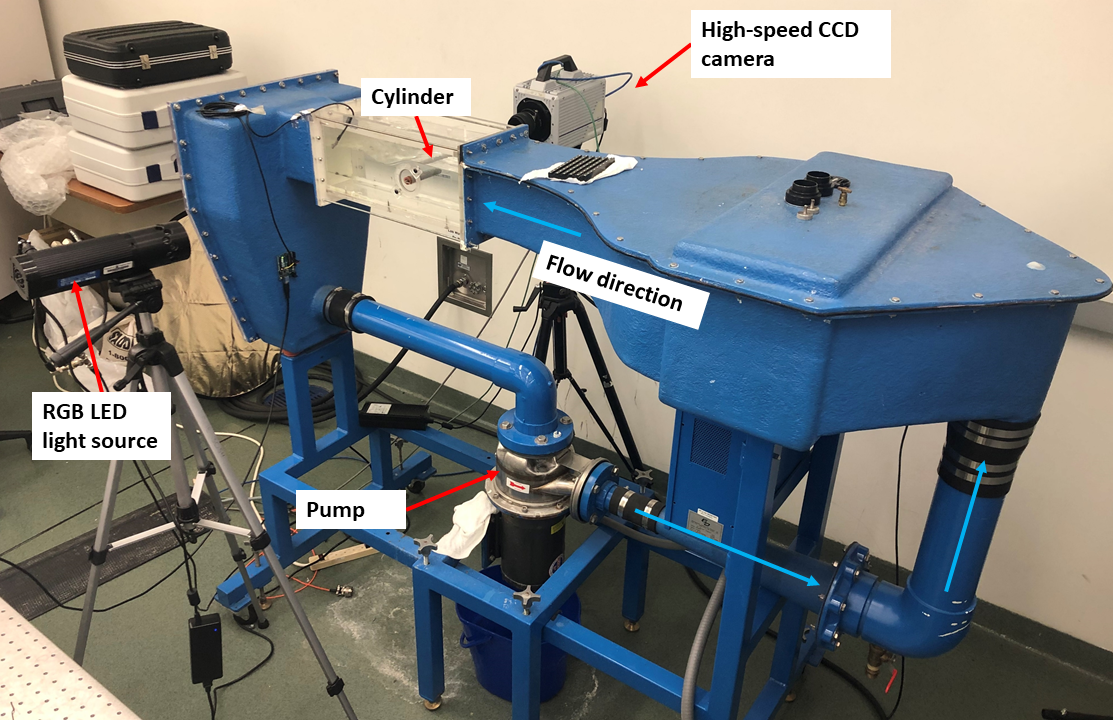

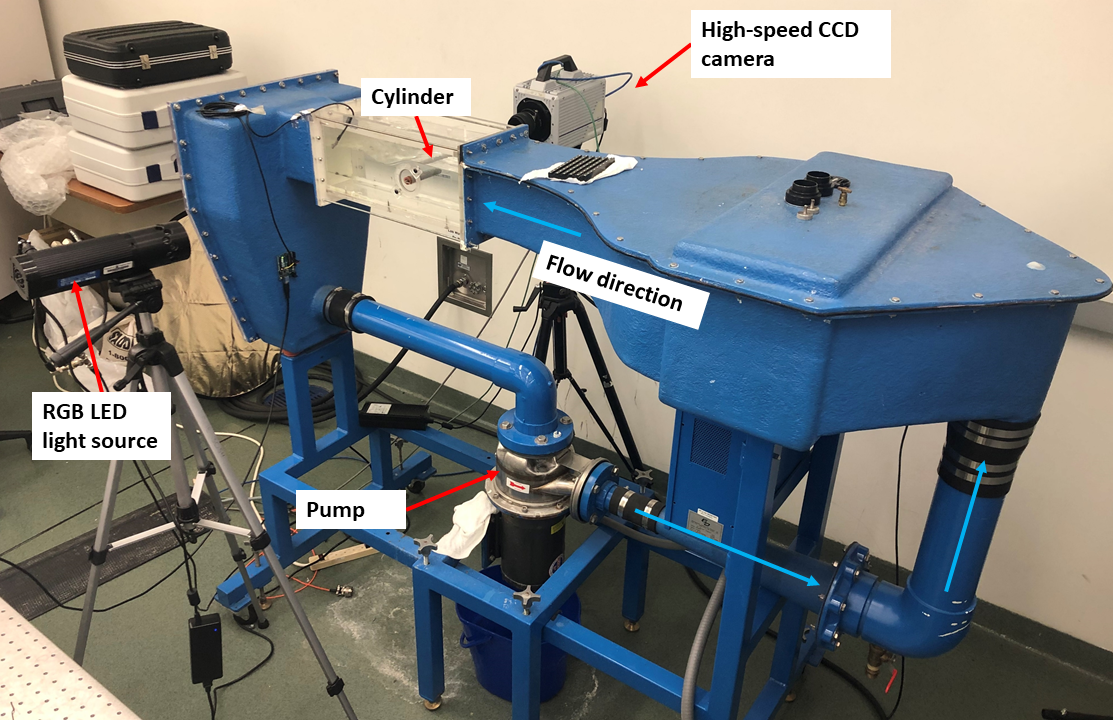

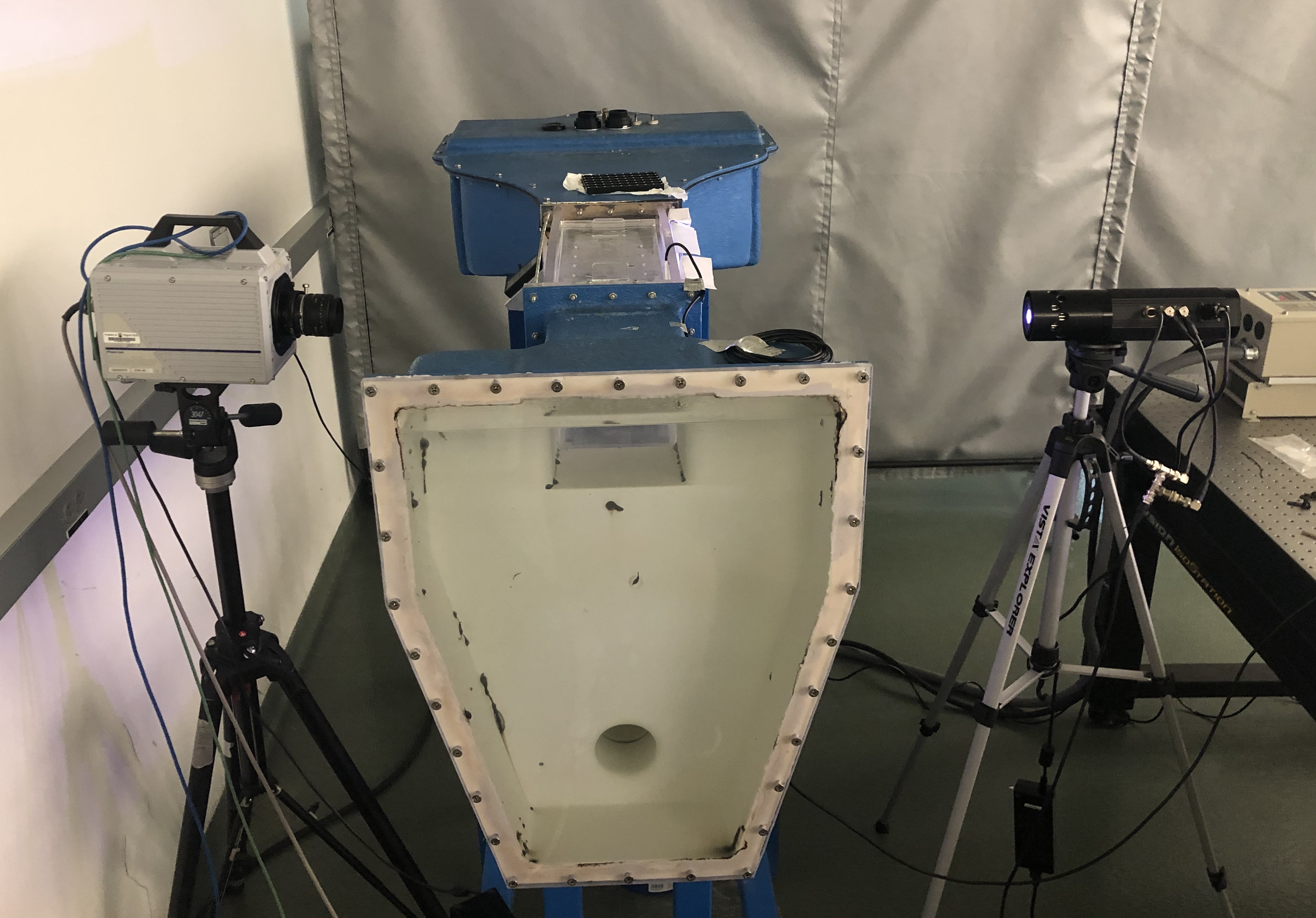

A. Water Tunnel.

You will be using a water tunnel with a test volume cross section of

6" x 6". This water tunnel, built by Engineering Laboratory and

Design Inc., has a vertical closed circuit arrangement, see Figure

5. On top of the flow circuit is the test section, which is enclosed

by 1/2" thick Plexiglas sheets. The test section has nominal

interior dimensions of 6"x6"x18" and can be operated with or without

a free surface. Flow is driven through the circuit by a 1.5HP

centrifugal pump that can deliver up to 280 gallons per minute. Flow

arrives in the test section through a settling chamber containing a

plastic honeycomb and three 60% porosity screens designed to

straighten the flow, make it more uniform and reduce turbulence

levels. A contraction at the downstream end of the settling chamber

further improves the flow quality by accelerating the flow to test

speed. Flow speed in the test section can be continuously varied

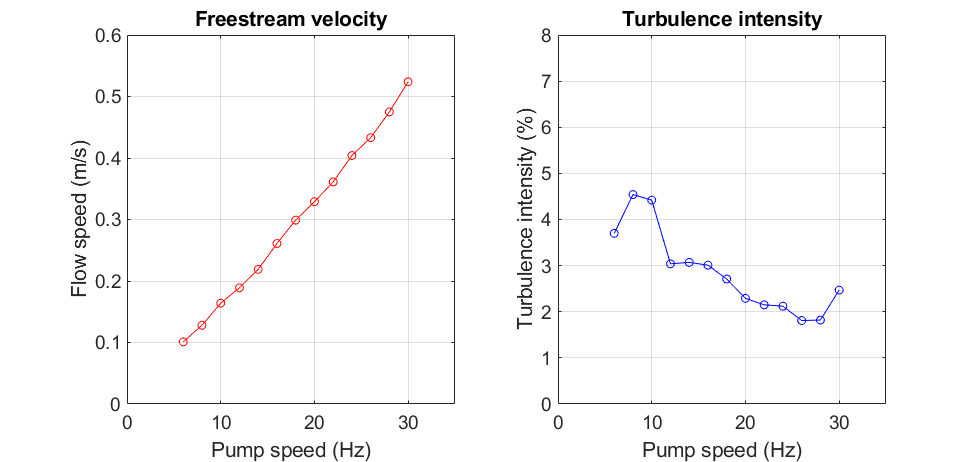

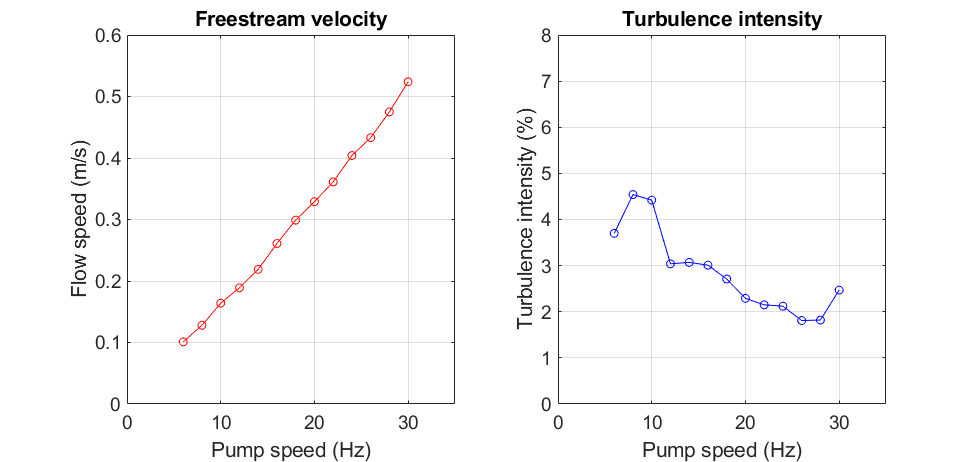

from zero to more than 2.5 ft/s by varying the pump speed. Figure 6 shows the nominal flow speed

and turbulence intensity in the test section as a function of the

pump speed when empty. Note that you can check the set velocity in

the test section yourself using the PSV during your experiment if

you want, and get an idea of the uncertainty by investigating the

properties of the flow outside of the wake.

Figure 5. The water tunnel used in this experiment.

Figure 5. The water tunnel used in this experiment.

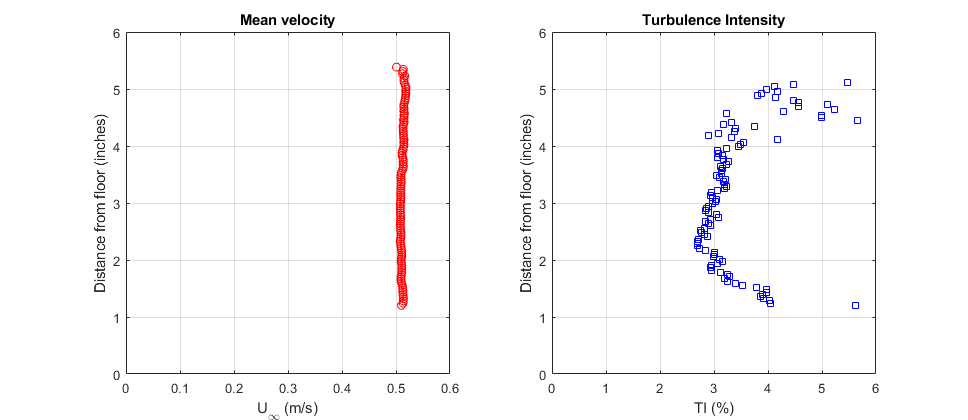

Figure 6. Velocity and turbulence intensity as a function of

pump speed in the empty water-tunnel test section.

The measurements were made 2" downstream of the test section

entrance.

The turbulence intensity is defined as the RMS of the fluctuating

component of the velocity signal (the actual velocity minus its time

averaged value) divided by time average velocity. RMS stands for

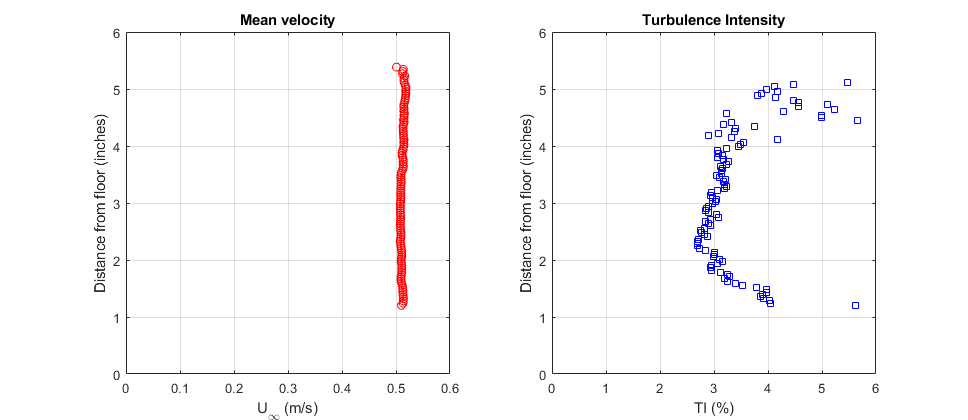

'root mean square' which is another term for standard deviation. Figure 7 shows

mean velocity and turbulence intensity profiles measured in the

empty test section for pump speed of 30 Hz.

Figure 7. Vertical velocity profiles in the empty test section

2" downstream of the test section entrance for a pump speed of

30Hz. Coordinate y is measured from the bottom of the test

section

The mean velocity is closely uniform varying less than 1% over the

measured distance. Turbulence intensity is about 3% at the center of

the test section. You can get an idea for what this means by

assuming the velocity fluctuations are distributed as a Gaussian, in

which case the velocity would be within two standard deviations

(twice the turbulence intensity) of its mean value 95% of the time.

3% is a fairly high compared to, say, the Stability Wind Tunnel

(0.02%). However, it is not atypical of water flow facilities of

this type.

B. Cylinder model

A circular cylinder with 0.75 inches in diameter is mounted close

to the mid height of the test section, see Figure 8. The cylinder

is manufactured from aluminum and spans the entire test section

width (that means, of course, that the ends of the cylinder are in

the boundary layers on the side walls of the water tunnel test

section).

Figure 8. The cylinder in the test section of

the water tunnel.

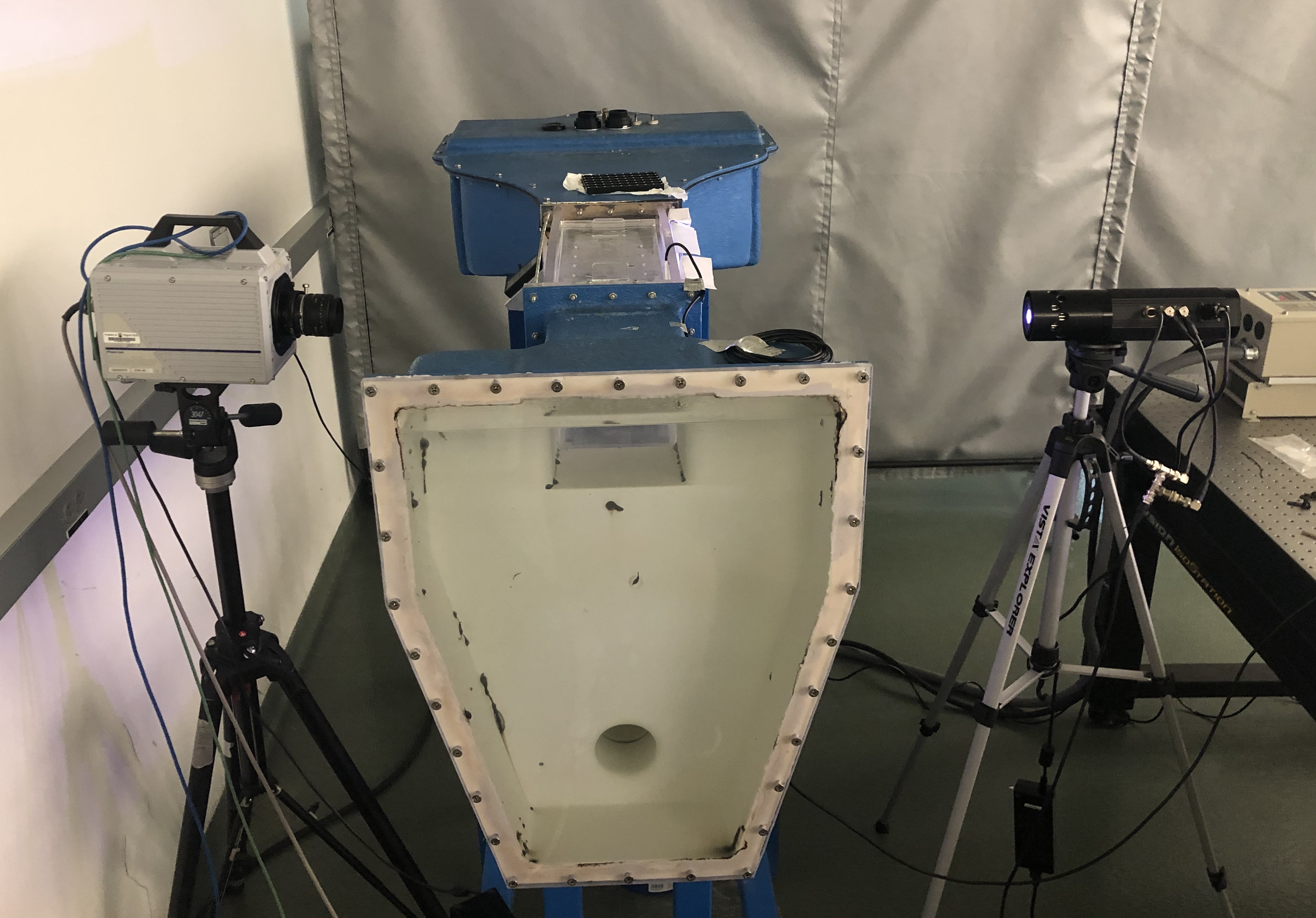

C. Particle Shadow Velocimetry System

You will employ a 1c2D PSV system (1 camera, 2D velocity

components) for this experiment, see Figure 9. The system uses an

LM2X-DMHP-RGB type 3-Color LED Light Source made by Innovative

Scientific Solutions, Inc. The LED light will be pulsed at 500 ms

intervals for a time period of 180 microseconds.

The camera is a Photron FASTCAM SA1.1 with a 50mm focal length

and an aperture of 8.0. The camera features a 1024 x 1024 pixel

sensor and is capable of 3,600 fps at full frame and up to

500,000fps when using partial frame. In this experiment, the

cameras will image the flow at 200Hz over an area of approximately

10 cm x 10 cm. For this experiment, the 1024 pixels x 1024 pixels

image is broken down into 64 pixels x 64 pixels interrogation

areas.

The fluid motion will be highlighted using gray particles called

microspheres. These particles are manufactured by Cospheric to

have a diameter between 250 and 300 microns and a density of 1

gram/ccm.

The system will be calibrated prior to your laboratory session.

However, the PSV system does not require the recalibration (unlike

PIV) as long as the camera and lens settings (focal distance and

aperture) is not modified. Taking a benefit of this feature, the

camera and the light source has been mounted on a table with a

traversing system responsible for moving the light source and the

camera in the streamwise direction. You will therefore have the

freedom to choose where to take data with the PSV system within

the entire volume of the test section.

Figure 9. The overall view of the PSV setup in

the water tunnel.

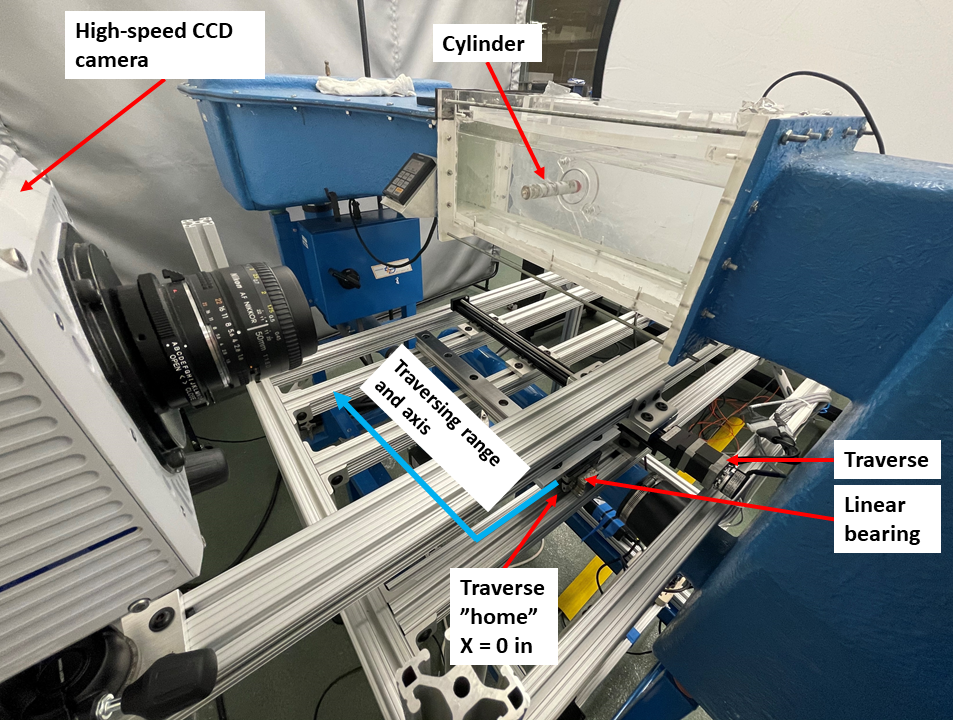

D. Traversing system

The high speed camera and the light source are mounted on an

aluminum bar and can be traversed along the streamwise direction

using a VelmeX traversing stage and a linear bearing. The former is

responsible for positioning the optical system while the latter

carries the mechanical load. You can use the traverse to vary the

location of the field of view in the streamwise direction. This

allows you to acquire data both upstream and downstream of the

cylinder.

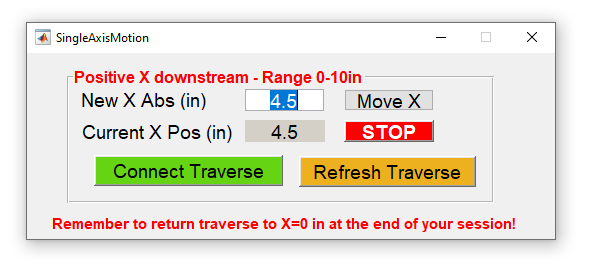

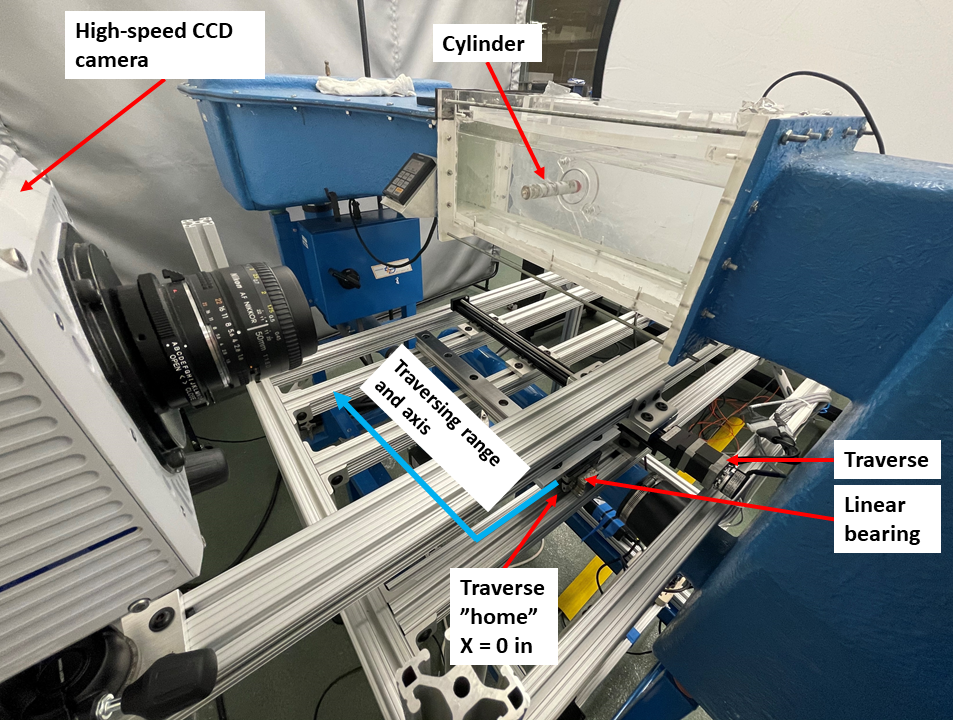

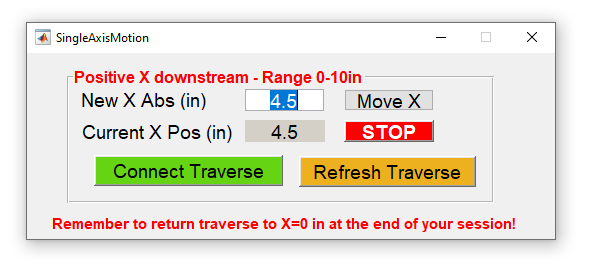

The CAD view of the traversing system is shown in Figure 10, while a

close-up annotated picture of the system is shown in Figure 11. Note

that the "home" of the traverse is at the downstream end of the

traversing axis, corresponding to X=0 in with X increasing upstream

of this location. The traverse can be operated using the Matlab GUI

shown in Figure 12. You can run the GUI from "D:\AOE3054_MatlabGUIs"

and typing SingleAxisMotion in the Matlab command window then

hitting enter. First, connect to the traverse using the "Connect

Traverse" button. You can use the "Refresh Traverse" button to

update the Current X position of the traverse carriage. Use the New

X Abs input box to set a new requested X location (absolute

coordinate) and click on the Move X button to move the traverse. Please

make sure to return the traverse carriage to X=0 in at the end of

your session to help the next group.

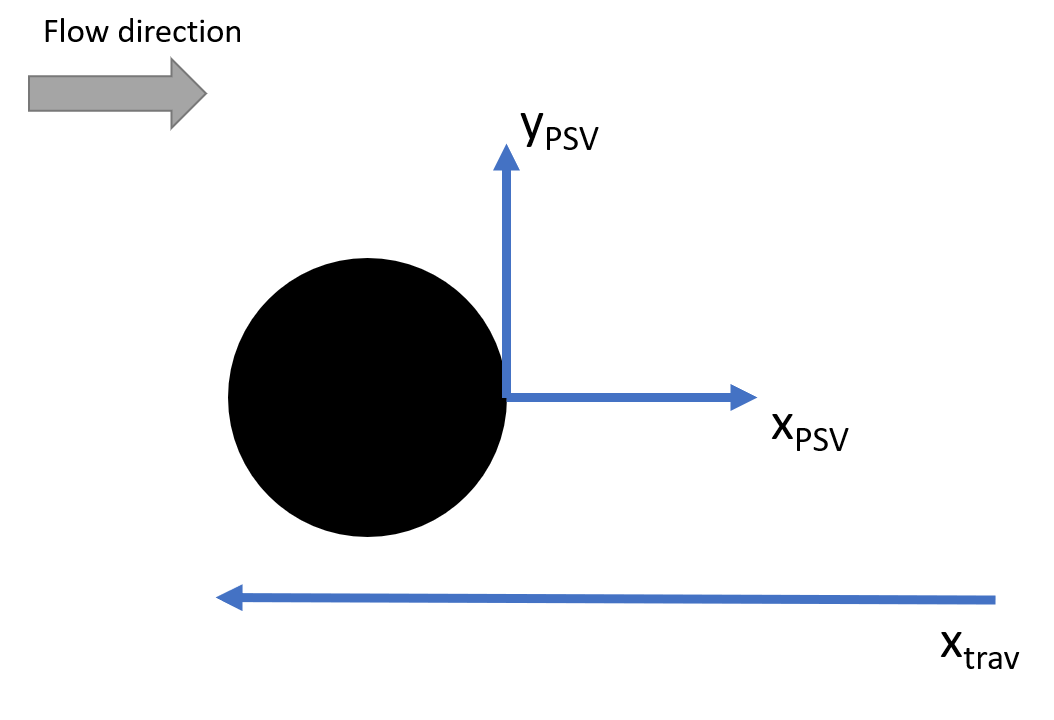

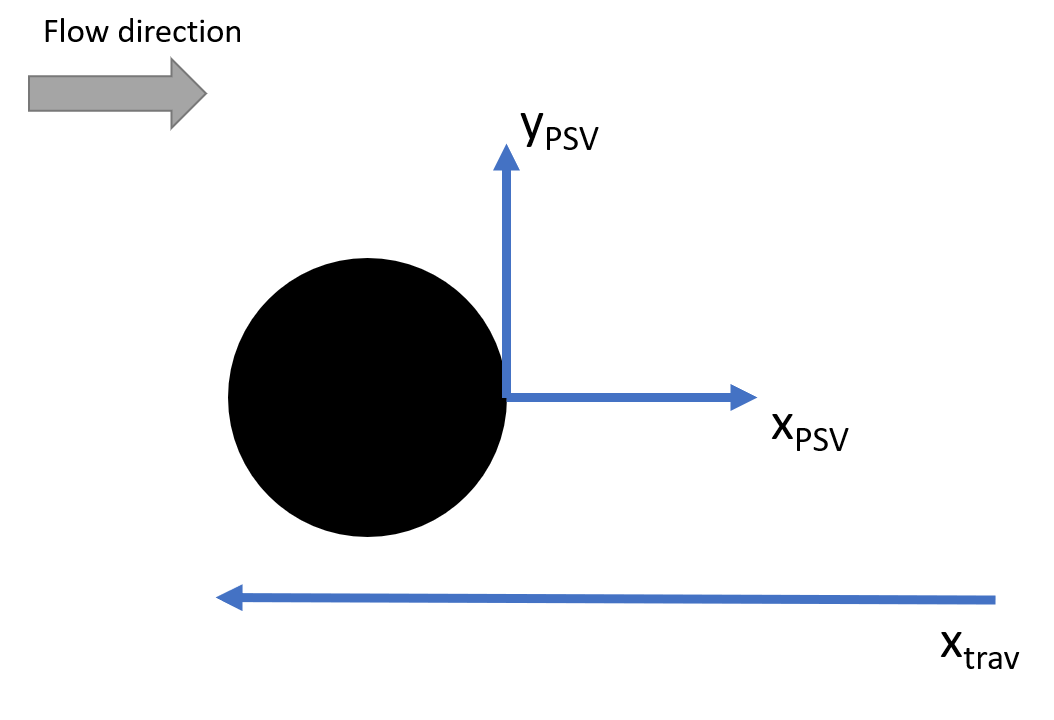

You will be using two coordinate systems: one is the coordinate

system of the traverse (1D with +X being opposite to the flow

direction) and the coordinate system of the PSV (2D: x,y). You will

need to keep log of where the traverse system is set and a

coordinate transformation will be provided to you that links the PSV

coordinate system and the traverse coordinate system.

Figure 10. The CAD view of the traversing system and

the PSV apparatus.

Figure 10. The CAD view of the traversing system and

the PSV apparatus.

The water tunnel has been made transparent to improve

visibility.

Figure 11. The close-up view of the traversing

system.

Figure 11. The close-up view of the traversing

system.

Figure 12. The Matlab GUI used for

controlling the traversing system.

E. Operational instructions

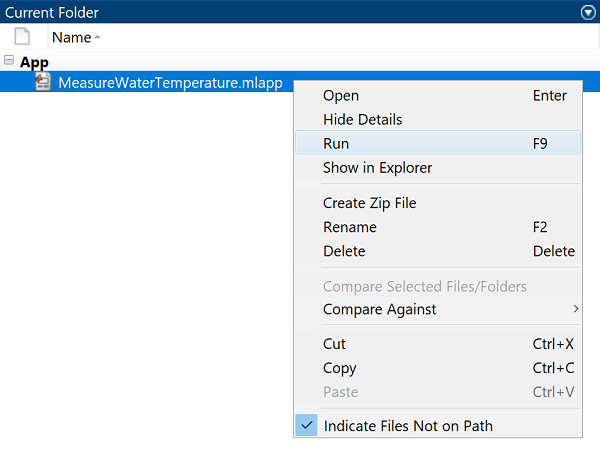

During your experiment, you will be changing the pump speed

using the Matlab GUI interface shown in Figure 13(a). You can run

the GUI from Matlab after navigating to the following directory:

"D:\AOE3054_MatlabGUIs". The GUI can be run by right clicking on

file "FanControlStandAlone_App.mlapp" and choosing the "Run"

option as shown in Figure 13(b). The software will ensure that the

inverter driving the motor of the pump will follow the speed (in

unit of Hz) you set in the GUI. The software contains all safety

features necessary for you to operate the pump over a wide range

of conditions in a continuous manner. The lowest speed the pump

can operate is 6 Hz, and the highest speed is 30 Hz. Below 6 Hz,

the AC motor driving the fan would not obtain sufficient amount of

cooling, and above 30 Hz, the flow starts interacting with the

ceiling of the water tunnel. You can operate the tunnel using the

following steps:

-

Connect to the pump controller using the Connect button. Once

successful, you will be prompted the "Connected" message in the

status indicator.

-

Set a desired speed in Hz (anywhere between 6 Hz and 30 Hz)

and click "Set Pump Speed". The pump speed will stabilize in 10

seconds, the GUI will countdown from 10 to 0 s and will prompt you

the Current speed in Hz and the current flow speed in m/s.

-

You can stop the pump by clicking the STOP button. Make

sure you stop the pump once you finished acquiring data and/or

at the end of your lab session.

You will have access to the water tunnel using PTZ (pan tilt

zoom) cameras. You are encouraged to take screenshots of the

apparatus as they are operated for your logbook and to move the

PTZ camera around to get a better view of the equipment and the

measurement apparatus.

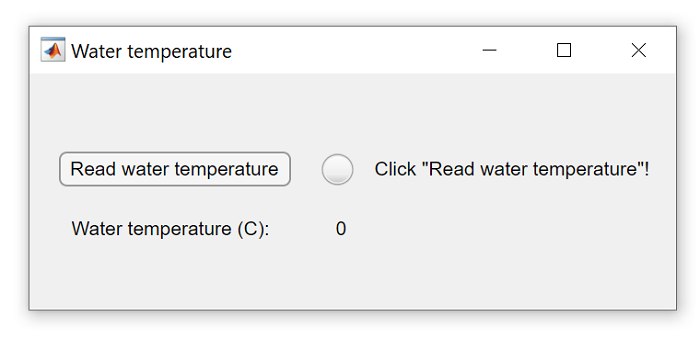

F. Instrumentation for Measuring the Properties of Water

Unlike air, the properties of water are remarkably constant with

pressure (an increase in the atmospheric pressure by a factor of

100 would only have a 0.5% effect on density). They are however a

function of temperature. You will use another Matlab GUI that

obtains readings of the water temperature using a waterproof

DS18B20 digital temperature sensor (see Figure 4) operated by an

Arduino Uno board. According to the manufacturer, the sensor has a

±0.5℃ accuracy within the -55 and 125℃ temperature range. In

Matlab, you can run the GUI by right clicking on its name

("D:\AOE3054_MatlabGUIs\MeasureWaterTemperature.mlapp") and click

on Run. Once ready, click on the "Read water temperature" button,

which will obtain a temperature reading, see Figure 15. The

measurement takes less than a minute. Repeat the measurement as

many times you need throughout your experiment.

Figure 15. Obtain water temperature using the

Matlab GUI.

Tables for the density and kinematic viscosity of

water can be found in numerous textbooks (e.g. Shames, 1992). The

following calculator uses a quintic fit to these tables. The

uncertainties in the curve fits are ±4x10-9 m2s-1

and ±0.04kg m-3

G. Coordinate system

You will be using two coordinate systems during your lab session,

one is the coordinate system of the PSV equipment and the other is

the traverse system, see Figure 16. The PSV coordinate system is

defined at the downstream end of the cylinder while the traverse

coordinate system points in the opposite direction and it is

measured from the "home" of the traverse. In your lab report, you

will be expected to use a third, global coordinate system. On the

desktop of the computer running the experiment, you will find a text

file called "CoordinateTransformation.txt" which will contain the

current information on how to relate the two local coordinate

systems to each other.

Figure 16. The coordinate systems used in the experiment.

Figure 16. The coordinate systems used in the experiment.

3. Theory

A. Ideal flow model of flow past a circular cylinder

In AOE 3014 you studied irrotational incompressible flow past a

circular cylinder without circulation (see Bertin, 2001, Section

3.13). Such a flow can be generated by adding a uniform flow, in the

positive x direction to a doublet at the origin directed in

the negative x direction. Of particular interest here is the

velocity distribution predicted by the theory which is given, in

terms of polar coordinates and components centered on the cylinder

axis, by the relations:

.........................(1)

where the symbols are defined in Figure 17 and R is

the cylinder radius (D/2). In terms of Cartesian

components and coordinates centered on the cylinder axis, the same

velocity field is:

.........................(1)

where the symbols are defined in Figure 17 and R is

the cylinder radius (D/2). In terms of Cartesian

components and coordinates centered on the cylinder axis, the same

velocity field is:

.........................(2)

.........................(2)

Figure 17. Definition of coordinates and components for

cylinder flow theory.

4. Practical Work

A. Getting familiar with the equipment and ready for an

experiment

The following procedures are designed to help you get a feel for

the water tunnel, the cylinder model and the PSV software. Feel

free to play with the apparatus at this stage, but don't forget to

record any results, thoughts, ideas or concerns in the logbook.

Setting up a PSV experiment to make a measurement from scratch can

take days, so don't feel frustrated if, in the space of a 2-hour

45-minute lab, the measurements don't go too quickly or the data

rate is slow. You are obtaining research-quality measurements

using cutting edge technology, each data set you get is a

significant achievement.

For information regarding software instructions, see section 7.

- The PSV system will have already been turned on by your lab TA

and will be ready for use when you arrive in the lab.

- Acquire a data set and look at the raw images. Do you see the

cylinder? Do you see the particles? Are they moving with the

flow?

- Note that you need to ensure that the overhead lights (directly above the water tunnel) are turned off (ask your TA for assistance). Since you are acquiring images at 200Hz,

the 60Hz flickering of the lights will lead to variations in the brightness of the particles seen by the camera and contaminate your measurements. An illustration of this is provided in Figure 18 below:

Figure 18. Impact of overhead lights on particle brightness (animation extracted from Bright field correction results from the DaVis software).

Figure 18. Impact of overhead lights on particle brightness (animation extracted from Bright field correction results from the DaVis software).

- Export the mean velocity field and look at the magnitude of

the vectors? What is the freestream velocity? What is the

velocity in the wake? Do these make sense? Are they consistent

with Figure 6? Discuss among the group what it shows. Also,

discuss in the group where in the flow you expect the vertical

component to be large.

- Try changing the flow speed using the Matlab GUI. How does

speed affect the PSV measurement? Does it work just as well?

Think about a good flow speed to measure at.

- Note the water temperature again. Has it changed? Will you be

able to assume its constant, or will you have to re-measure it

periodically? Can you estimate the cylinder Reynolds number,

from the velocity measurement outside of the wake and the

temperature? What flow regime shall your measurements fall based

on the Reynolds number?

B. Designing and Implementing an Experiment

When you feel comfortable with the equipment it is time to choose

some goals and decide on a strategy to achieve them. Suggested goals

are given below. Of course, you are encouraged to choose a different

goal of your own, or adapt these goals, but the goals you end up

with must be scientific, and clearly stated in the logbook. Note

that, as always, your grade does not depend upon how many goals you

achieve, but on how complete, careful, scientific and documented

your work is. Neither does your grade depend upon how close your

results agree with any other pre-conceived ideas of what the answers

should be. Instead it depends upon how open mindedly and objectively

you assess your results, their qualities and limitations, and what

they appear to show. Also, remember that processing the PSV data

will be time consuming (about 5-6 min per data set), so structure

your measurements such that you can achieve your goal(s) even if you

end up getting fewer measurements than may initially seem possible.

When planning your objectives and measurement schedule, count on the

PSV to acquire data in about 1 min.

Goal 1. Design and implement a series of tests to

determine the shape and form of the circular cylinder wake at the

center span at a fixed Reynolds number.

Suggestions. Don't forget to record and explain your

choice of conditions (i.e. flow speed) and measurement locations

in the logbook. If you measured wake structure in Experiment 3, at

the much higher Reynolds number of the wind tunnel, measuring at

some of the same streamwise locations (relative to the cylinder

center and its diameter) would also provide a valuable comparison.

Its usually easiest to measure the wake in a series of vertical

profiles. Don't forget you can measure both vertical and

horizontal velocity components. (If you measure both vertical and

horizontal mean velocities at the same actual points you can

determine the magnitude and direction of the mean velocity vector

at each point). Analyze and plot your results as you go.

Re-measure any funny looking points. Keep careful documentation of

what you do, why you do it, set up characteristics, expected

results, unexpected results, analysis, photos and plots in the

electronic lab book as you proceed. Ideally, you would want to

measure the velocity upstream of the cylinder (since it is the

freestream velocity you will use to normalize all your results).

You can traverse the light and camera to image the flow upstream of the cylinder to do so.

Make you are carefully documenting where you take this measurement. Will this measurement be

contaminated by the presence of the cylinder? How so? Could you

use the continuity equation to work out the free-stream velocity?

How does that compare to the data the Matlab GUI prompts you?

Analysis suggestions for later. Basically, you want to

present and describe your mean velocity flow field as clearly as

possible, reveal the shape and form of the flow, and compare that

with Experiment 3 or any theoretical model you are aware of. When

post-processing your data, try using the mean velocity field

information to visualize the streamlines of the flow. Mean

velocity profiles show the time average shape of the flow. Look at

the individual images. They show what the flow looks like at each

instant. Linking these views is good discussion.

Goal 2. Design and implement a series of tests to

examine the flow over the front of the cylinder at center-span a

set Reynolds number, and compare with ideal flow theory.

Suggestions. The issue here can be "how good is the ideal

flow solution over the front of the cylinder, since the flow here

isn't separated". Record and explain your choice of conditions for

your measurement (i.e. flow speed) and measurement locations in

the logbook. Choose your measurement locations to make the

comparison with the theory as straightforward as possible. Don't

forget you can measure both horizontal and vertical velocity

components. Determine how you can obtain vorticity from the

velocity field. Checking the freestream velocity outside the wake

of the cylinder might be a wise thing to do since knowing the free

stream velocity is critical to compare with the theory. Analyze

and plot your results as you go. Re-measure any funny looking

points. Keep careful documentation of what you do, why you do it,

set up characteristics, expected results, unexpected results,

analysis, photos and plots in the electronic lab book as you

proceed. Analysis should include uncertainty estimates for all

results.

Goal 3. Identify the flow regimes the cylinder generates

in its wake by mapping out the flow's Reynolds number, Strouhal

number and induced drag.

Suggestions. Calculate the Strouhal number using

instantaneous velocity data, calculate the drag coefficient using

time-averaged velocity data. Plot the results as a function of

Reynolds number and compare it to other measurement results (see

Ref 3). How does your results differ and why? How does the

turbulence intensities differ from the data presented in the

literature? How does the Strouhal number change with flow speed?

How does this compare to data presented in the literature?

Time management

The group should leave few minutes at the end of the lab period

for discussion and to check that everybody has everything they

need.

You will need to use your own cloud server (such as Google Drive

or Dropbox, etc.) to transport your data from the lab

computer running the experiment to your own device. Make sure

you have access to a cloud service. Within your cloud, you will

need 350 Mb of free space per one instantaneous data set. For

time-averaged data, you will need 10 Mb of free space. Prior

to your experiment, make sure you prepare enough space in

your cloud and include the link to your cloud provider in your

logbook. Use a web browser on the laboratory computer

during your lab session to upload your data to your cloud.

Alternatively, you may use a file sharing website, such as this one, to transfer your

data from the PSV computer to you own. Keep in mind that data

transfer might take up to 15 minutes.

5. Recommended Report

Format

Before starting your report read carefully all the requirements in Appendix 1.

Title page

As detailed in Appendix

1 .

Introduction

Begin this section by stating logical objectives that fit what

your data has shown you.

Then explain in summary form what was done to achieve the

objectives. You could follow this with a background discussion of

what PSV is and what sources of error there are and/or a

description of the basis of ideal flow theory for the circular

cylinder. If you can draw on any material additional to the manual

that is good. Finishing with a summary of the layout of the rest

of the report would work well.

Apparatus and Instrumentation

This section is probably easiest to write in two parts (though

that is not required), one dealing with the water tunnel and the

other with the PSV. In describing the water tunnel give all

details relevant to the experiment (e.g. closed circuit,

contraction ratio, dimensions and shape of test section, flow

quality in the empty section at test conditions, flow speed range

and control etc.) You might include here some of your measurements

(e.g. of the inflow velocity) if they are relevant to describing

the characteristics of the facility, as opposed to the cylinder

flow. Also describe the model, its dimensions, its method of

mounting, its vertical position when mounted, the traverse its

accuracy etc. In describing the PSV, explain what type of system

was used, its optical characteristics, the components of the

system, the location of the measurement volume in the test

section, software etc..

To describe all of this, diagrams and/or labeled photographs,

screenshots are very necessary. Take what you like from the

manual, but be sure to reference it. You will have to show at

least one figure showing the water tunnel test section, model, and

model mount in relation to the PSV measurement area. Make sure

your figure(s) are dimensioned properly. Include your

uncertainties in primary measurements in this section

Results and Discussion

A good way to begin is to briefly state what measurements were

made and at what locations and conditions. You should also include

here definitions of the statistical quantities plotted (e.g. mean

velocity, mean vorticity etc...), and explanations of how their

uncertainties were calculated and what those uncertainties were.

You should reference a table (copied out of your Excel file) or

appendix containing the uncertainty calculation. Early on in the

results and discussion (or even in the apparatus and

Instrumentation) you need to define a coordinate system, and any

key normalizing variables, using a diagram and description in the

text, e.g. "The coordinate system to be used in presenting results

is shown in figure ??. Coordinate x is measured downstream

from the cylinder center, y vertically upwards from that

center and z, directed so as to complete a right-handed

system is measured from the center span location. Velocity

components u and v are defined in the directions x

and y. Distances will in general be normalized on the ???

and velocities on the approach velocity measured at x=??,

y=??, z=?? )".

If you have them, now would be a good time to introduce any

flowvis pictures. Don't just describe what the static pictures

show, use the pictures as a springboard to describing what you

actually saw.

Next introduce your profile plots - the kind of wording

suggested in experiment 3 will work just fine here. Now describe

in detail the plots and error estimates. Then discuss what their

significance is given the goals/ objectives you have chosen (look

again at the suggestions given with the goals above). One workable

approach is to describe what appears on each of the plots in turn,

using a separate paragraph for each, inserting sentences of

discussion as you go e.g. "Figure ?? shows the profile of uRMS

(normalized on free-stream velocity) plotted against y

measured at x=?? and z=??. At the limits

of the profile, turbulence levels are low at about ?? and

reasonably consistent with values measured in the empty test

section of ?? (see AOE 3054 Course Manual, 2016, Experiment 4).

Presumably these points lie outside the cylinder wake. The wake

edges appear to be marked by the large increases in uRMS

at around y=?? and ??. The fact that velocity

fluctuations in the wake should be larger than outside is

consistent with turbulence being present in...".

Make sure your results and discussion include (and justify) the

conclusions you want to make and that those conclusions connect

with your objectives (if not, change the discussion or the

objectives).

Conclusions

Begin this section with one or two sentences describing what you

did. Then draw your conclusions, each numbered and starting on a

separate line. Each conclusion should summarize an important piece

of information that was revealed or taught by the experiment. Make

sure the conclusions cover all the points addressed by your

objectives and all the important points of your discussion. Note

that no new material should appear in the conclusions. It should

be possible to write them by simply lifting key sentences from the

rest of your report (mostly the Results and Discussion). Also note

that the conclusions should stand by themselves, though you may

refer to the figures if you wish.

6. References

- Bertin J.J. 2001, Aerodynamics for Engineers , 4th

edition, Prentice Hall.

- Shames I. H., 1992, Mechanics of Fluids, Third

Edition, McGraw Hill, New York.

- Panton R. L., 2013, Incompressible Flow, 4th edition, Wiley,

New York.

7. Addendum: Running the

PSV Software

Compile your logbook on a different computer to that running the PSV

software.

Follow the software step-by-step instructions below. It is paramount

that you follow these directions precisely as the data acquisition

software is complicated and error that you make while using it can

compromise its delicate setup.

If the PDF below does not display properly, you can download it manually here.

You should now be ready to use this system to meet your goals. Don't

forget when taking the next or any subsequent measurement to change

the name of the output file or the old data will be overwritten.

Each run will generate a series of 200 images and DaVis will export an associated set of 199

data files for the instantaneous velocity field and 9 files for the average quantities (Keep in mind that exporting data does take several minutes).

You can use a combination of exported data and screenshots from the DaVis results for your logbook,

but keep in mind you will need all your data files exported for the analysis in your report.

Store your data (instantaneous and averaged) for each run in separate folders. You can then download this

PIV Data Matlab Importing package - Updated 14 Sep 2021

to import the data from all your files (the 199 instantaneous and 9 averaged quantities) within a set and consolidate it in matrix form in Matlab.

You can then use these MAT files and write your own codes to perform further analysis and generate plots. A description of the contents of this package is provided below:

Content of the AOE3054_PIV_Import_Rev1 Package:

- AOE3054_PIV_ImportInstant_2020.m: you will run this function on the 199 instantaneous velocity files

to import that data into Matlab. The code will create a MAT file (whose name you will specify) with four variables:

- X and Y are the streamwise and vertical coordinates of the measurement locations. The X and Y matrices have a size of MxM.

- U and V are the velocity component matrices and will be MxMx199 matrices since you obtain components for each consecutive pair of the 200 images.

- AOE3054_PIV_ImportMean_2020.m: you will run this function on the 9 averaged

quantity files to import that data into Matlab. The code will create a MAT file (whose name you will specify) with 12 variables:

- X and Y are the streamwise and vertical coordinates of the measurement locations

- U and V are the velocity components at those points

- Umag is the velocity magnitude

- stdU and stdV are the standard deviation at each point on the grid (computed over the 200 images)

- AKE and TKE are the average and total kinetic energy

- Rxx, Rxy, and Ryy are the Reynolds stresses

- Two folders containing a sample data set are provided in the ZIP file so you can test the import codes and debug your own plotting codes ahead of your experiment:

- 20HzSampleData_Instantaneous: 199 instantaneous velocity files acquired at a pump speed of 20Hz.

- 20HzSampleData_Averages: 9 averaged quantities acquired at a pump speed of 20Hz.

.........................(1)

.........................(1) .........................(2)

.........................(2)